Our Magnetic Particle Testing

Services Include:

Surface Crack Detection: Identify surface and near-surface cracks with high precision, ensuring material integrity.

Weld Inspection: Ensure the quality and strength of your welds with our thorough magnetic particle inspection.

Maintenance and Inspection: Regular maintenance and inspection services to extend the lifespan of your equipment and prevent failures.

Dye Penetrant Testing Services Compliant with Australian Standards

we offer top-notch dye penetrant testing services, specifically tailored for the manufacturing, mining, and oil & gas industries. Our advanced non-destructive testing techniques ensure that your materials and equipment meet the highest standards of safety and reliability.

Industry-Specific Expertise: Our certified technicians understand the unique challenges of the manufacturing, mining, and oil & gas sectors, delivering precise and reliable results.

Surface Crack Detection: Accurately identify surface cracks and discontinuities to ensure material integrity in critical components.

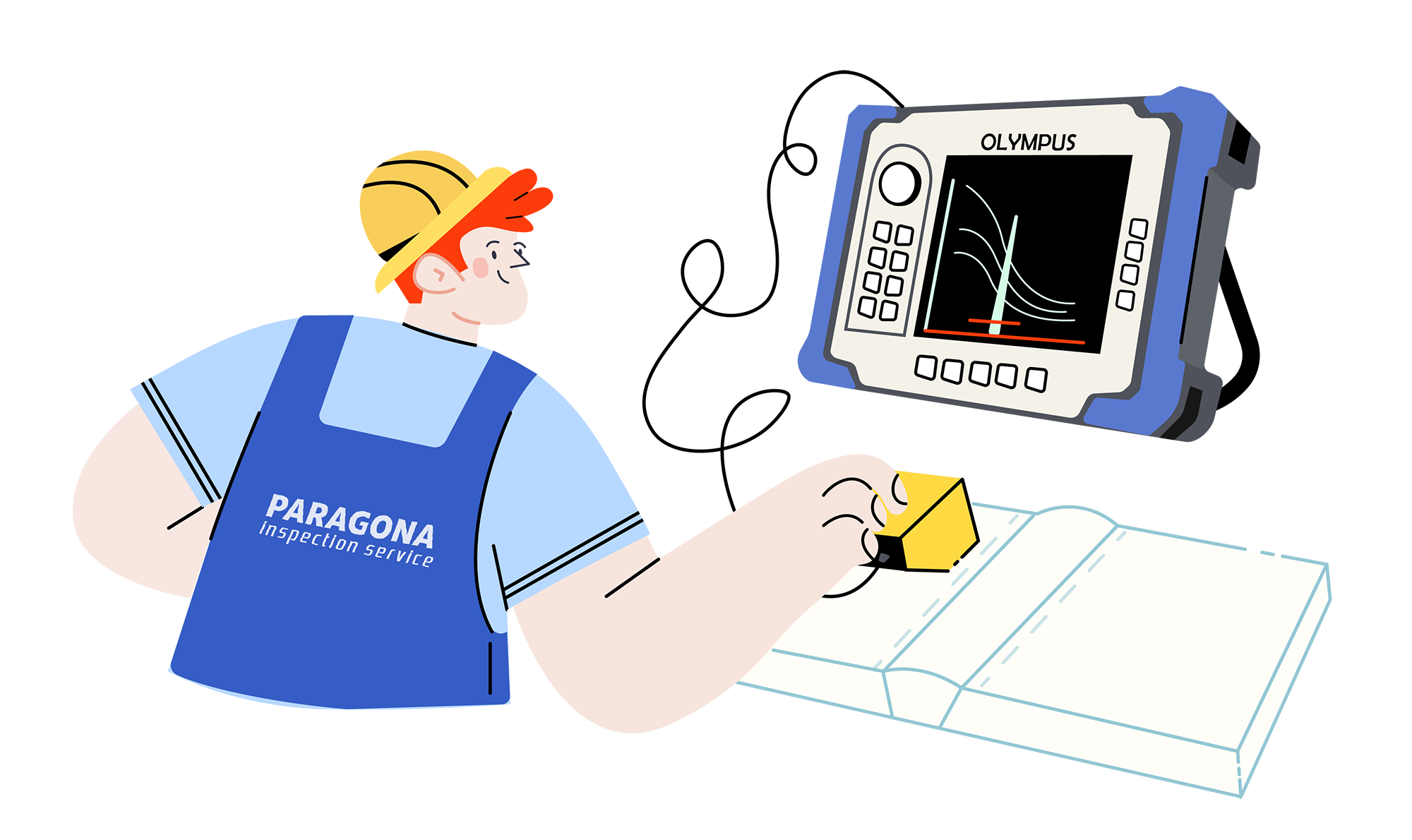

Why Choose Our

Ultrasonic Testing Services?

Precision and Accuracy: Our state-of-the-art ultrasonic testing equipment ensures precise measurements, helping you detect even the smallest flaws or defects in materials.

Experienced Technicians: Our team of certified technicians brings years of expertise to every project, guaranteeing exceptional results every time.

Cost-Effective Solutions: By using advanced non-destructive testing methods, we help you avoid costly repairs and downtime, ensuring your operations run smoothly.

Comprehensive Reports: We provide detailed reports with actionable insights, helping you make informed decisions about your materials and products.

Versatile Applications: From aerospace to manufacturing, our ultrasonic testing services are suited for a wide range of industries and applications.

Our Ultrasonic Testing Services Include:

Weld Inspection: Ensure the integrity of your welds with our thorough ultrasonic weld inspection services.

Thickness Measurement: Accurately measure the thickness of materials, even in hard-to-reach areas.

Flaw Detection: Identify internal defects such as cracks, voids, and inclusions with high precision.

Corrosion Monitoring: Monitor and assess corrosion levels to prevent potential failures and extend the lifespan of your equipment.

Eddy Current Testing Services

we offer state-of-the-art eddy current testing services to ensure the integrity and reliability of your components and structures. Our advanced non-destructive testing (NDT) method is ideal for detecting surface and subsurface defects in conductive materials, making it perfect for industries such as aerospace, automotive, and manufacturing. Our certified technicians provide detailed, actionable reports that help you make informed maintenance decisions, ensuring compliance with industry standards and preventing costly failures. Trust us for accurate and efficient eddy current testing to keep your operations running smoothly. Contact us today to learn more.

Our Radiographic Interpretation (RI)

Services Include:

Volumetric Defect Detection: examination method capable of examining the entire specimen rather than just the surface.

Weld Inspection: Ensure the quality and strength of your welds with our thorough radiographic inspection.

Maintenance and Inspection: Regular maintenance and inspection services to extend the lifespan of your equipment and prevent failures.

Our Most Popular Features to make your Life easier than every before

Managed Bills and Costs

Clients value precise and dependable inspection reports that they can trust. Detailed and easy-to-understand reports that include clear findings, photographs, and recommendations.

Custom Client Support

Excellent customer service with clear communication and responsiveness to client inquiries and concerns. Offering tailored inspection services to meet the specific needs and requirements of each client.

Team to handle Requests

Highly skilled inspectors with certifications and a professional attitude can instill confidence in clients. Adherence to industry standards and obtaining necessary certifications to assure quality and compliance.

Safe and Secure Payments

Our Services

Transforming Needs into Solutions

Ultrasonic Testing (UT)

Ensuring material integrity with precise, non-invasive ultrasonic testing services.

Magnetic Particles Testing (MT)

Efficient flaw detection using advanced magnetic particle testing methods for safety

Visual Inspection (VT)

Ensuring product quality and compliance through meticulous visual inspection processes

Dye Penetrant Testing (PT)

Identifying surface flaws effectively using advanced dye penetrant inspection techniques

Eddy Current Testing (ET)

Ensuring material integrity and flaw detection with precise eddy current methods

Welding Inspection

Guaranteeing weld integrity and safety with thorough welding inspection techniques

Pressure Vessel Inspection

Expertly inspecting pressure vessels, ensuring compliance, safety, and integrity with thorough evaluations.

Storage Tank Inspection

Expert evaluations ensure the safety, compliance, and integrity of storage tanks through thorough inspections.

Piping Inspection

Ensuring safety and compliance through thorough inspections, maintaining the integrity of piping systems

We’re trusted by over 700+ Businesses all over the Australia